SERVICES

Activated carbon adsorption dry scrubber

Activated carbon adsorption dry scrubber

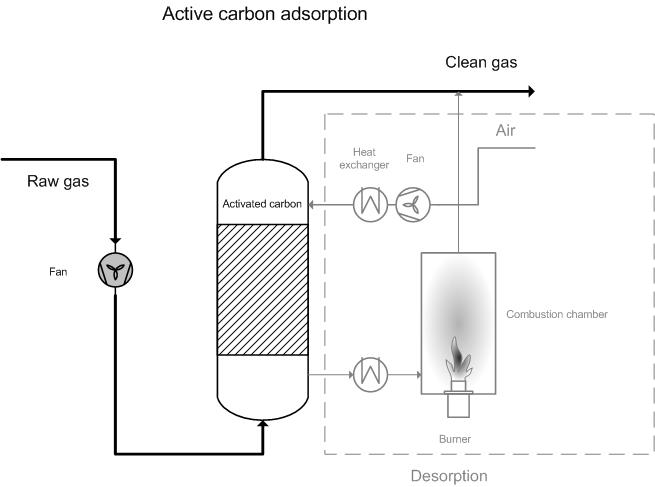

An activated carbon adsorption dry scrubber is an air pollution control device used to remove pollutants, including volatile organic compounds (VOCs), heavy metals, and odors, from gas streams. It operates by passing the contaminated gas through a bed of activated carbon, which has a highly porous structure and large surface area, allowing it to adsorb contaminants effectively. The process relies on physical adsorption, where pollutants adhere to the surface of the activated carbon. These scrubbers are commonly used in industrial applications, such as chemical manufacturing, waste incineration, and air purification systems, due to their efficiency, low maintenance requirements, and ability to handle a wide range of pollutants.

Working Principle

The gas stream is directed through a bed of activated carbon, which is highly porous and possesses an extensive surface area. As the contaminated gas flows through, pollutants such as volatile organic compounds (VOCs), heavy metals, and odors are captured and retained on the carbon’s surface. This adsorption occurs due to the van der Waals forces and, in some cases, chemical interactions between the pollutant molecules and the carbon. The scrubber operates without the need for liquids, making it a dry system that is relatively simple to maintain.

Features and Design

High Removal Efficiency

These systems are capable of capturing and removing a wide range of pollutants, including volatile organic compounds (VOCs), hazardous air pollutants (HAPs), odors, and even heavy metals, with efficiency rates often exceeding 95%. The activated carbon's highly porous structure and large surface area allow for effective adsorption of even low-concentration pollutants.

Versatile Construction Materials

The scrubbers are typically constructed using corrosion-resistant materials such as stainless steel, carbon steel, or fiberglass, depending on the specific needs of the gas stream and the operating environment. Stainless steel is commonly used for its strength, resistance to corrosion, and ability to high temperatures.

Customizable Design

These scrubbers can be tailored in terms of size, shape, and configuration to accommodate varying gas flow rates, pollutant types, and space constraints. The design can be adapted to handle specific contaminants, such as volatile organic compounds (VOCs), odors, or heavy metals, by selecting the appropriate grade of activated carbon.Additionally, features such as modular carbon .

Efficient Gas Purification Solutions

Fill out the form below to get more details.

Applications

Activated carbon adsorption dry scrubbers are utilized across a broad spectrum of industries due to their ability to efficiently remove pollutants and odors from gas streams.

- ☑ Adhesives

- ☑ Coating operations

- ☑ Chemical plants

- ☑ Drying oven

- ☑ Food processing

Frequently Asked Questions (FAQs)

It is a pollution control device that uses activated carbon to remove pollutants such as VOCs, heavy metals, and odors from gas streams through a dry adsorption process.

Contaminated gas is passed through a bed of activated carbon, where pollutants are adsorbed onto the carbon's porous surface due to physical and chemical interactions.

It removes a wide range of contaminants, including volatile organic compounds (VOCs), hazardous air pollutants (HAPs), odors, dioxins, and heavy metals.

Yes, depending on the application and pollutant type, activated carbon can be thermally or chemically regenerated to extend its lifespan.

Dry scrubbers are efficient, low-maintenance, and do not require water or other liquids, reducing operational costs and environmental impact.

Advanced monitoring systems track parameters like pressure drop, gas flow rate, and pollutant concentration. Regular maintenance includes inspecting and replacing carbon and ensuring proper flow distribution.