SERVICES

Odor control scrubber

Odor control scrubber

In the second stage, the exhaust gas is passed through a dry scrubber containing activated carbon. This additional filtration process acts as a polishing stage, where the activated carbon adsorbs the remaining contaminants, ensuring that the outlet air is free from any residual odor. The system’s counterflow operation maximizes efficiency by ensuring thorough contact between the exhaust gases and scrubbing media, optimizing the removal of pollutants.

Working Principle

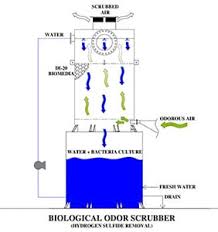

The odor control scrubber operates in two stages to ensure optimal removal of pollutants. In the first stage, the odorous gas enters the wet scrubber, where it interacts with a caustic solution that captures compounds like hydrogen sulfide (H2S), methyl mercaptan, and other sulfur-based odors. While the wet scrubber effectively removes a large portion of the odor, trace amounts may still be present in the exhaust. In the second stage, the gas enters a dry scrubber, where activated carbon adsorbs the remaining odor-causing components. The dual-stage process ensures a high level of odor removal, with efficiencies of up to 99.99%, resulting in clean, odor-free exhaust emissions.

Features and Design

Dual-Stage Scrubbing System

The Odor Control Scrubber utilizes a two-stage scrubbing process, first employing wet scrubbing followed by dry scrubbing to maximize odor removal. The wet stage removes the bulk of odor-causing agents, such as hydrogen sulfide and methyl mercaptan, using a caustic solution. The second dry stage acts as a polishing system, utilizing activated carbon to capture any residual pollutants in low concentrations. This dual approach ensures that emissions are thoroughly treated, meeting stringent environmental regulations and enhancing air quality. The use of two complementary stages improves overall scrubber efficiency, making it ideal for industries where odor control is critical.

High Removal Efficiency

The odor control scrubber is designed to offer high removal efficiency, with the ability to capture up to 99.99% of odorous compounds in exhaust gases. The wet scrubber effectively removes the majority of sulfur-based odors, while the dry scrubber further eliminates trace amounts of odors that may remain. This dual filtration ensures that the while the dry exhaust gas is free from any unpleasant smells before being released into the atmosphere. With such a high efficiency, the scrubber is ideal for industries like chemical plants, petrochemical facilities, and food processing plants, where even small amounts of odor can cause significant problems.

Versatile and Customizable Design

The Odor Control Scrubber can be customized to suit a wide range of industrial needs, offering flexibility in terms of material construction, airflow, and system size. The scrubber is available in various materials of construction (Mild Steel, SS 304, SS 316, FRP, PP, PVC), ensuring that it can withstand different chemical exposures and environmental conditions. The airflow rate can be adjusted to meet specific requirements, ranging from 100 CFM to 30,000 CFM. Customization options allow for tailored solutions that provide optimal performance for a wide variety of industries, including municipal waste treatment, asphalt manufacturing, and pharmaceutical companies.

Efficient Gas Purification Solutions

Fill out the form below to get more details.

Applications

- ☑ Chemical Plants.

- ☑ Petrochemical Facilities.

- ☑ Municipal Waste Treatment.

- ☑ Food Processing.

- ☑ Asphalt Manufacturing.

Frequently Asked Questions (FAQs)

The odor control scrubber operates in two stages: a wet scrubber removes most of the odor-causing compounds using a scrubbing solution.

The scrubber can effectively remove a wide range of odorous chemicals, including hydrogen sulfide (H2S), methyl mercaptan, dimethyl sulfide, carbon disulfide, and n-propyl mercaptan, commonly found in chemical, petrochemical, and food processing industries.

The scrubber offers up to 99.99% capturing efficiency, making it highly effective in removing even trace amounts of odor-causing agents from industrial exhaust gases.

The odor control scrubber can be constructed using various materials like mild steel, SS 304, SS 316, FRP, PP, and PVC, ensuring durability .

Yes, the scrubber is designed to accommodate air flow rates ranging from 100 to 30,000 CFM, making it adaptable to both small and large-scale industrial.

Yes, the odor control scrubber can be customized to meet the specific requirements of various industries, including adjustments to air flow rates, materials of construction.