SERVICES

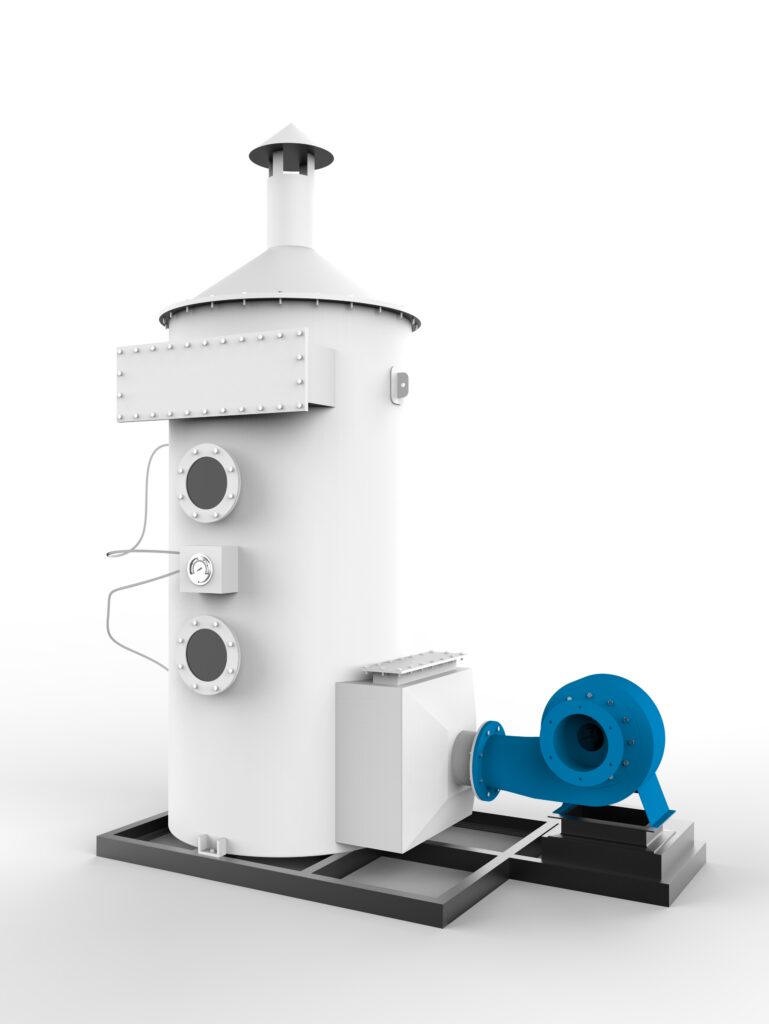

Hydrogen Sulfide Scrubber

Hydrogen Sulfide Scrubber

A hydrogen sulfide (H₂S) scrubber is an air pollution control device used to capture and neutralize hydrogen sulfide gas, a toxic and foul-smelling compound commonly produced in industries such as petroleum refining, natural gas processing, wastewater treatment, and chemical manufacturing. H₂S scrubbers typically use a scrubbing solution, such as an alkaline solution of sodium hydroxide (NaOH) or sodium bicarbonate (NaHCO₃), to chemically react with hydrogen sulfide. This reaction converts H₂S into less harmful compounds, like sodium sulfide or sodium bisulfide, which are then safely removed from the system.

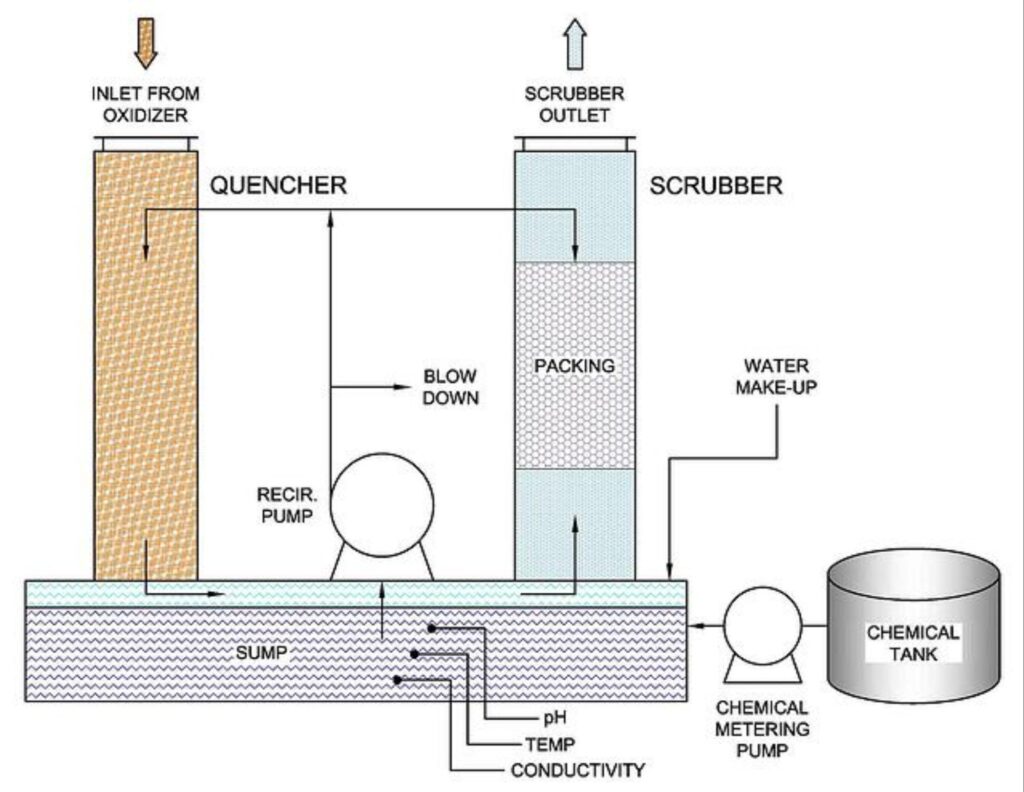

Working Principle

As contaminated gas flows into the scrubber, it is passed through a scrubbing solution, typically an alkaline solution such as sodium hydroxide (NaOH) or sodium bicarbonate (NaHCO₃). The H₂S gas reacts with the alkaline solution, forming byproducts like sodium sulfide or sodium bisulfide, which are much less harmful than hydrogen sulfide. This chemical reaction neutralizes the H₂S, converting it into solid or soluble compounds, which are then separated from the gas stream.

Features and Design

High Removal Efficiency

These scrubbers are capable of achieving removal efficiencies of 95% or higher, depending on factors such as the design of the system, concentration of H₂S, gas flow rate, and the quality of the scrubbing solution used. The efficiency of the scrubber is enhanced by the chemical reaction between H₂S and the alkaline solution, which ensures that even low concentrations of H₂S are effectively neutralized.

Versatile Construction Materials

Since H₂S is a corrosive gas, materials used in the construction of the scrubber must withstand the chemical properties of hydrogen sulfide and the often aggressive scrubbing solutions. Common materials include stainless steel, which is highly resistant to corrosion and oxidation, making it ideal for both wet and dry scrubber systems.

Customizable Design

The scrubber's size, capacity, and configuration can be adjusted based on factors such as the flow rate of gas, the concentration of H₂S, and the available space within a facility. Key design elements, including the type of scrubbing medium (wet or dry), the number of scrubbing stages, and the type of contact system (packed bed, spray tower, or venturi), can be optimized to achieve the highest removal efficiency.

Efficient Gas Purification Solutions

Fill out the form below to get more details.

Applications

These scrubbers are crucial in the petroleum refining industry, where they are used to remove H₂S from natural gas and refinery streams during the desulfurization process, ensuring compliance with air quality standards.

- ☑ Chemicals industry

- ☑ Waste incineration installations

- ☑Pharmaceutical industry

- ☑ Storage and transfer of chemicals

- ☑ Surface treatment

Frequently Asked Questions (FAQs)

A hydrogen sulfide scrubber is an air pollution control device designed to capture and neutralize hydrogen sulfide gas emissions from industrial processes, preventing the release of harmful H₂S into the atmosphere.

The scrubber works by passing hydrogen sulfide-containing gas through an alkaline solution (such as sodium hydroxide or sodium bicarbonate) or solid absorbents. The H₂S reacts with the scrubbing solution, forming byproducts like sodium sulfide or sodium bisulfide, which are then safely removed.

H₂S scrubbers are widely used in industries such as petroleum refining, natural gas processing, wastewater treatment, chemical manufacturing, food and beverage production, pulp and paper manufacturing, and landfill gas management.

Maintenance frequency depends on the system design and operational conditions. Regular checks are necessary to monitor the scrubbing solution, inspect for clogging or wear, and ensure the scrubber is operating at optimal efficiency.

H₂S scrubbers are typically constructed from corrosion-resistant materials such as stainless steel, fiberglass, polypropylene, or PVC. These materials are chosen for their ability to withstand the harsh conditions posed by hydrogen sulfide and the scrubbing solution.

The lifespan of an H₂S scrubber depends on its design, the materials used, and how well it is maintained. With proper care, scrubbers can last for many years, though components such as scrubbing solutions or filters may need to be replaced periodically.