SERVICES

Hydrogen Fluoride Scrubber

Hydrogen Fluoride Scrubber

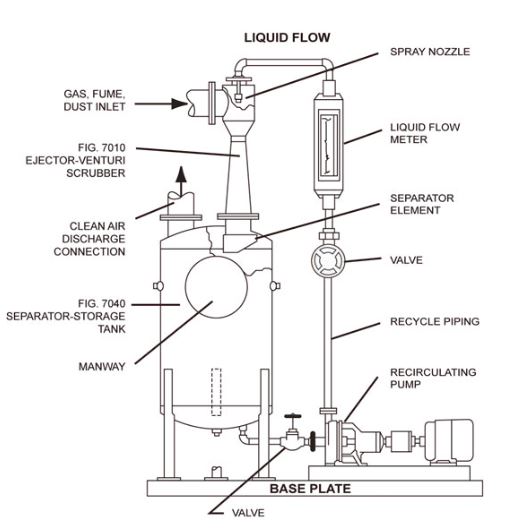

A hydrogen fluoride (HF) scrubber is a specialized air pollution control device designed to capture and neutralize hydrogen fluoride gas emissions, which are highly toxic and corrosive. These scrubbers are commonly used in industries such as petroleum refining, aluminum production, and chemical manufacturing, where HF is produced as a byproduct or during certain processes.The scrubber works by passing the contaminated gas through a scrubbing medium, which typically consists of an aqueous solution of alkaline substances like sodium hydroxide or calcium hydroxide.

Working Principle

As contaminated gas containing HF enters the scrubber, it passes through a chamber where it comes into contact with the scrubbing medium, typically an aqueous solution of alkaline compounds such as sodium hydroxide (NaOH) or calcium hydroxide (Ca(OH)₂). The HF reacts with the alkaline solution to form neutral compounds, such as sodium fluoride (NaF) or calcium fluoride (CaF₂), which are much less harmful than HF.process is typically facilitated by a countercurrent flow of gas and liquid, ensuring optimal contact time and reaction efficiency.

Features and Design

High Removal Efficiency

These scrubbers can achieve removal efficiencies of 95% or higher, depending on factors such as the design of the system, the concentration of HF, the scrubbing medium used, and the contact time between the gas and the neutralizing solution. The scrubber's effectiveness is enhanced by the chemical reaction between HF and the alkaline solution, which efficiently converts the toxic gas into harmless by products.

Versatile Construction Materials

Since HF is highly corrosive, the materials used in the construction of the scrubber must be resistant to corrosion, erosion, and chemical attack. Common materials include stainless steel, which offers excellent resistance to corrosion and high temperatures, making it ideal for the internal components of the scrubber that come into direct contact with the HF gas and scrubbing solution.

Customizable Design

These scrubbers can be designed to handle different flow rates, HF concentrations, and operational environments, ensuring effective emission control. Key design elements such as the size of the scrubber, type of scrubbing medium, and the number of stages can be adjusted based on the specific pollutants being treated and the space constraints of the facility. For instance, the use of multi-stage scrubbing systems.

Efficient Gas Purification Solutions

Fill out the form below to get more details.

Applications

Hydrogen fluoride (HF) scrubbers play a critical role in various industries where HF is produced as a byproduct or released during manufacturing processes. In petroleum refining, they are used in alkylation units to capture HF emissions generated during the production of high-octane gasoline additives.

- ☑ Chemicals industry

- ☑ Waste incineration installations

- ☑Pharmaceutical industry

- ☑ Storage and transfer of chemicals

- ☑ Surface treatment

Frequently Asked Questions (FAQs)

A hydrogen fluoride scrubber is an air pollution control device designed to capture and neutralize hydrogen fluoride gas emissions from industrial processes using an alkaline scrubbing solution or solid absorbents.

The scrubber works by passing contaminated gas through a scrubbing medium, typically an aqueous alkaline solution like sodium hydroxide or calcium hydroxide, which chemically reacts with HF to neutralize it and convert it into less harmful byproducts such as sodium fluoride or calcium fluoride.

HF scrubbers are used in industries such as petroleum refining, aluminum production, chemical manufacturing, semiconductor fabrication, fluorine production, waste incineration, and pharmaceutical or agrochemical manufacturing.

The maintenance frequency depends on the system’s design and operating conditions, but regular inspections are required to monitor the condition of the scrubbing solution, check for clogging or corrosion, and ensure that the system is operating efficiently.

Yes, HF scrubbers are designed to handle varying concentrations of HF. The design and size of the scrubber can be adjusted based on the concentration and flow rate of HF gas to ensure effective removal.

Yes, HF scrubbers are designed to protect the environment by preventing the release of hazardous HF emissions into the atmosphere. They help industries comply with air quality standards and reduce their environmental footprint.